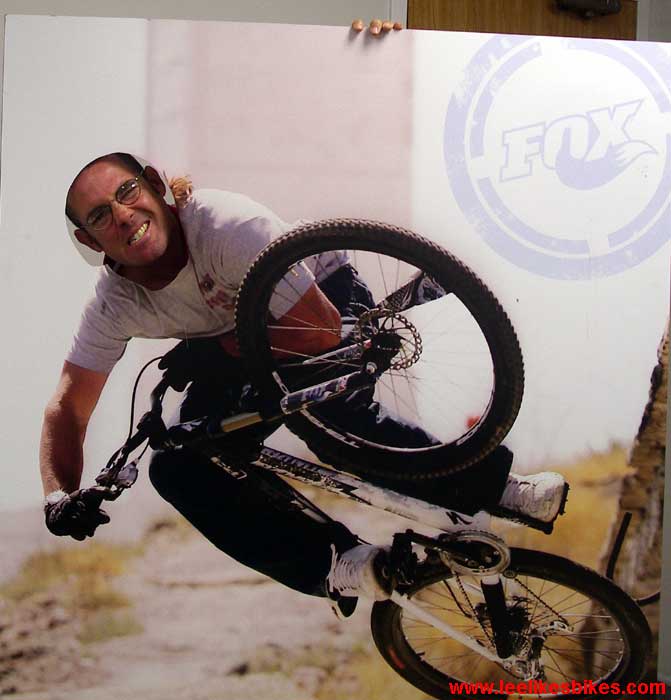

FOX Racing Shox factory tour

Yesterday I visited some friends at FOX Racing Shox in Watsonville, Calif., and they gave me the sweet factory tour.

It’s quite the operation. The things that struck me most:

– It’s all about process. The assembly floor is a study in manufacturing best practices. Every step — every inch, every fixture — has been thought out to maximize efficiency.

– It’s all about quality. FOX tests quality at every stage, from checking raw materials and outsourced parts to measuring components to fatigue-testing complete forks and shocks. They go to a LOT of trouble to make sure everything is dialed.

Receiving

Fabricating

Assembling

Testing

Special thanks to Mark Fitzsimmons and Elayna Caldwell.

Comments are closed.